A bimetal or thermostatic metal is a sheet or strip of two or more composite materials having different coefficients of linear thermal expansion bonded by riveting, brazing or welding. The material with the larger coefficient of thermal expansion (CTE) is considered as the active component, and that of smaller CTE is the passive component. The active component usually has alloys containing iron, manganese, nickel, or chrome in varying amounts. Whereas on the passive side, invar is often chosen, an iron-nickel alloy containing 36% nickel. Some bimetals include a third layer of copper or nickel in between the active and passive sides in order to increase thermal conductivity and decrease the material’s electrical resistivity [1, 2].

What is Bimetal?

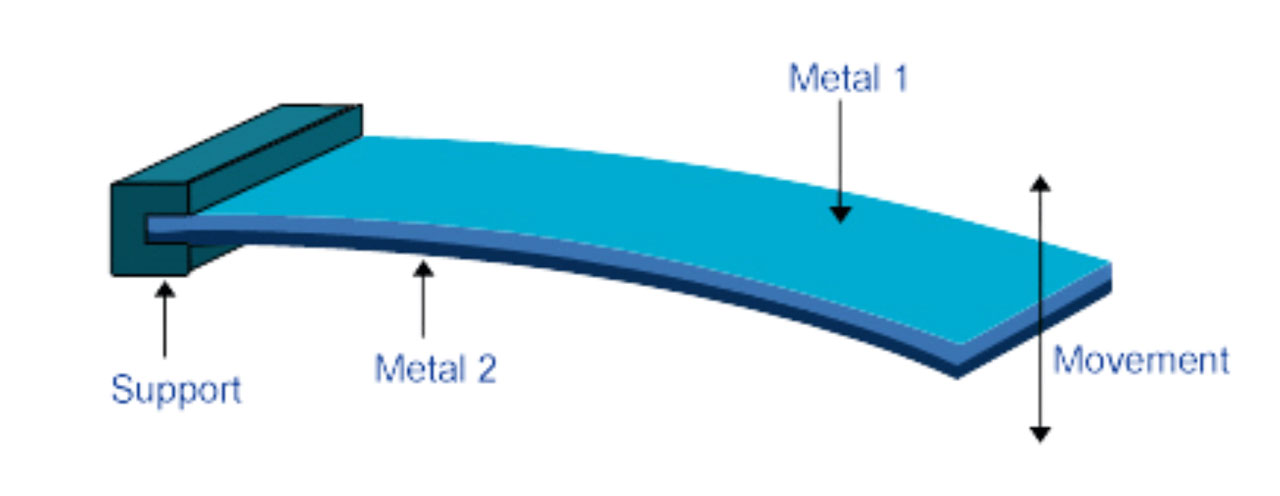

Bimetals work with the tendency of metals to expand when heated, and contract when cooled. The resultant change of curvature, or bending, in reaction to temperature change, is a fundamental property of all thermostatic bimetals. In effect, the temperature change is converted into mechanical displacement. The workings used for bimetals are selected for their temperature characteristics as well as their stability, thermal conductivity, strength, workability, and electrical properties.

Flexivity: also known as specific curvature is an important property of bimetals that is defined by the curvature change along its longitudinal axis. The thermostatic bimetal bending is directly proportional to temperature change of the component strips and the difference in the CTE, and inversely proportional to the thickness of the combined strips. The radius of curvature is also affected by the thickness ratio and the ratio of the moduli of elasticity of the two strips.

Electrical Resistivity and Thermal Conductivity: For applications where heat is created by passing an electric current through a bimetal, information of the electrical resistivity and thermal conductivity as factors for temperature change is important. Because of this property for many bimetals that are used as circuit breakers.

Bimetal applications

Temperature Control: Bimetals are utilized as a means to control the temperature, as in room temperature thermostats. In such devices, a bimetal blade holds a current-carrying contact point that is linked to a coupled static contact point. This allows for the automatic switching of circuits to control heating and cooling of electrical devices as the blade arches when a certain temperature is reached.

Temperature Indication: Bimetals finds applications for temperature indication as in the spiral or helix actuated pointer thermometers. Such thermometers help measure temperatures in offices, refrigerators, and even on aircraft wings. The temperature range covered by bimetals extends approximately between -50°F and 1000°F (-46°C and 538°C). Angular deflection rate is usually at 2.5-3° per degree Fahrenheit.

Function Control: By introducing heat to a bimetal – or what is known as auxiliary heating – the function of a device containing the bimetal can be controlled. Circuit breakers and time delay devices are examples of these devices. Relative functions such as current and time can be controlled by installing the bimetal piece as the active element in the device.

Tube and Pipe Couplings: For non-magnetic, cryogenic, and nuclear applications where metal properties can be switched reliably, bimetallic couplings are utilized to allow direct connection and transition for pipes and tubes with different CTEs. These types of fittings are also used in other thermal transfer applications.