In the realm of modern engineering, innovation is the cornerstone of progress. One such marvel that has been transforming industries is the ingenious fusion of two distinct metals – Bimetals. These alloys possess a dynamic synergy, combining the unique strengths of each metal to create a material that outshines its individual components. Join us as we delve into the world of bimetal, unravelling its potential and uncovering the myriad possibilities it offers to the forward-looking industrialists.

Introduction to Bimetal Plates

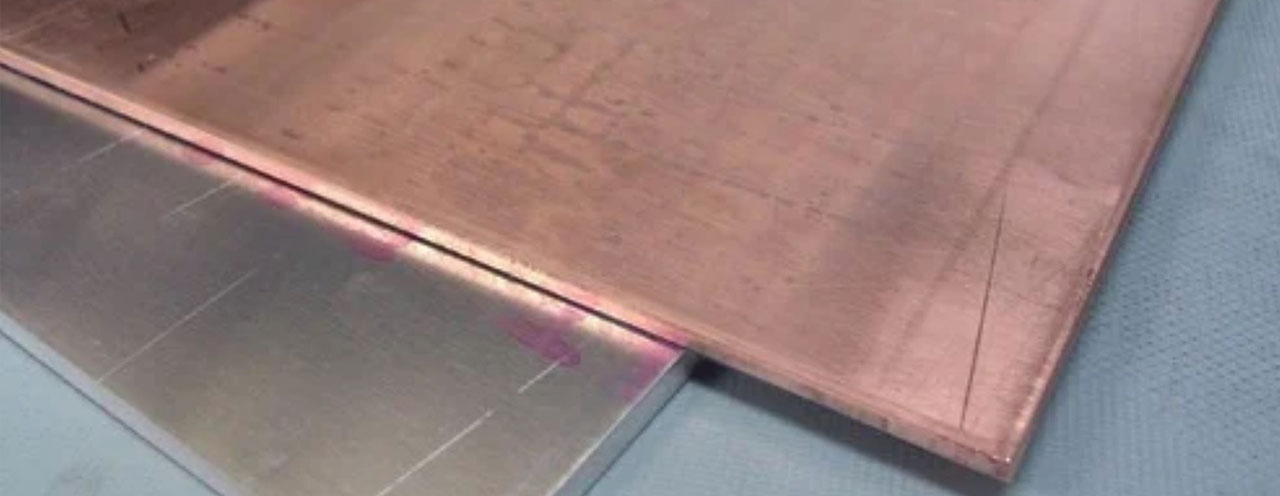

Bimetal plates, also known as composite or clad plates, are innovative engineering materials designed to combine the advantages of two different metals into a single, high-performance unit. These plates are engineered to meet specific requirements where conventional monometal materials fall short. By fusing distinct metals with complementary properties, bimetal plates offer a versatile solution to challenges in various industries.

Bimetal plates consist of two layers of different metals, each chosen for its unique characteristics. One layer, known as the base metal, provides structural integrity and support, while the other layer, referred to as the clad metal, imparts specific properties like corrosion resistance, wear resistance, or high-temperature tolerance. The combination of these metals creates a material that outperforms its individual components.

How are Bimetal Plates Manufactured?

The manufacturing process of bimetal plates involves several techniques, primarily including cladding, inlaying, and edge welding. Cladding involves joining the base and clad metals through methods like explosive welding or hot rolling. Inlaying incorporates the clad metal into the base metal through processes such as diffusion bonding or brazing. Edge welding, as the name suggests, welds the two metals at their edges, creating a seamless bond.

Key Components and Composition: The success of bimetal plates hinges on the careful selection of base and clad metals. The base metal typically possesses high strength, ensuring structural stability, while the clad metal provides specific properties like corrosion resistance, heat resistance, or electrical conductivity. Common base metals include steel or aluminum, while materials like copper, nickel, or stainless steel are frequently used for cladding. The composition ratio can be fine-tuned to meet precise engineering requirements, making bimetal plates highly customizable for a range of applications.

Applications of Bimetal Plates

Bimetal plates find extensive use across diverse industries due to their unique combination of properties. Let’s explore some key sectors where these innovative materials play a pivotal role:

- Aerospace Industry: In the aerospace industry, where lightweight yet high-strength materials are crucial, bimetal plates offer an ideal solution. They are employed in critical components like aircraft wings, fuselage sections, and engine components. Bimetal plates provide a balance between structural integrity and resistance to extreme conditions, making them integral in ensuring the safety and efficiency of aerospace vehicles.

- Electrical Engineering: Bimetal plates are indispensable in electrical engineering applications, particularly in components that require precise control of electrical conductivity and thermal expansion. They are used in circuit breakers, switches, and other electrical devices where the ability to handle high currents and withstand thermal stress is essential. The combination of metals in bimetal plates ensures optimal performance and reliability in these critical applications.

- Automotive Sector: The automotive industry benefits from bimetal plates in various ways. These plates are utilized in components such as engine bearings, piston rings, and clutch facings. Bimetal plates enhance wear resistance and reduce friction, leading to improved efficiency and longevity of automotive systems. Additionally, their ability to withstand high temperatures and harsh operating conditions makes them a valuable material in the automotive manufacturing process.

4. Industrial Machinery: Bimetal plates play a pivotal role in the realm of industrial machinery. They are integrated into components like gears, bushings, and bearings, where durability, strength, and resistance to abrasive forces are paramount. By combining metals with complementary properties, bimetal plates ensure that machinery can operate reliably under demanding conditions. This, in turn, contributes to increased productivity and reduced maintenance costs.

Choosing the Right Bimetal Plate for Your Application

Selecting the appropriate bimetal plate is a critical step in ensuring optimal performance and longevity in your specific application. Several factors must be taken into consideration to make an informed choice.

Considerations for Material Selection

The choice of materials in a bimetal plate is fundamental to its performance. It’s imperative to evaluate the properties of both the base metal and the clad metal. Consider factors such as:

- Mechanical Properties: Assess the required strength, hardness, and ductility for the application. Choose a base metal that provides the necessary structural support, and a clad metal with the desired special properties (e.g., corrosion resistance, wear resistance).

- Compatibility: Ensure that the selected metals are compatible in terms of thermal expansion coefficients and other material behaviors. This prevents issues arising from differential expansion or contraction.

- Cost-effectiveness: Strive for a balance between performance and cost. While exotic materials may offer exceptional properties, they might not always be cost-effective for the intended application.

Size and Thickness Considerations

The dimensions of the bimetal plate are crucial factors to take into account. This includes both the overall size and the thickness of the plate. Consider the following:

- Physical Constraints: Assess the available space and structural limitations of the application. Ensure that the chosen bimetal plate fits seamlessly within the design parameters.

- Thickness Ratio: Optimal performance is achieved when the base metal provides the necessary structural support while the clad metal imparts the desired properties. The thickness ratio should be carefully calculated to achieve this balance.

- Tolerances and Machining Allowances: Consider the machining processes involved and any required tolerances. Choose a plate thickness that allows for machining without compromising performance.

Environmental Factors

The operating environment significantly impacts the performance and longevity of bimetal plates. Take into account the following environmental considerations:

- Temperature Range: Determine the expected temperature range the bimetal plate will be exposed to. This helps in selecting metals with suitable thermal stability and resistance to thermal expansion.

- Corrosion and Chemical Exposure: Evaluate whether the application involves exposure to corrosive substances or chemicals. Select a clad metal that offers resistance to these elements.

- Abrasion and Wear: Consider the potential for abrasive forces or wear over time. Choose a clad metal that provides the necessary wear resistance to maintain performance.

Pearl Overseas: Your Prime Supplier

As a leading supplier of Bimetal products, Pearl Overseas stands out as a reliable source for high-quality materials. With a reputation for excellence and a track record of satisfied customers, Pearl Overseas is committed to delivering products that meet the highest industry standards.

Why Choose Pearl Overseas?

- Extensive Product Range: Pearl Overseas offers a wide range of Bimetal products, including plates, sheets, strips, and washers. This diverse inventory ensures that you have access to the right product for your specific application.

- Quality Assurance: All Bimetal products supplied by Pearl Overseas undergo rigorous quality checks to ensure they meet stringent industry standards.

- Customization Options: Pearl Overseas understands that each project has unique requirements. That’s why we offer customization options, allowing you to tailor Bimetal products to your exact specifications.

- Competitive Pricing: Pearl Overseas is dedicated to providing cost-effective solutions without compromising on quality. By leveraging our expertise and industry connections, we are able to offer competitive pricing on our Bimetal products.

- Expertise and Support: The team at Pearl Overseas is knowledgeable about Bimetal products and their applications. We can offer expert advice and guidance to help you select the right product for your specific needs.

Pearl Overseas is your go-to supplier for high-quality Bimetal products. Our extensive range, commitment to quality, customization options, competitive pricing, and expert support makes us a trusted partner in your quest for the right Bimetal solution. With Pearl Overseas, you can navigate the world of Bimetal products with confidence, knowing that you’re making the right purchase for your unique needs.