Duplex Steels have a two-phase microstructure consisting of grains of ferritic and austenitic Duplex Steel. The word “duplex” denotes the two-phase microstructure of ferritic and austenitic steel grains. The ferritic and austenitic Duplex Steel grades have approximately equal proportions (i.e., 50% each) in Duplex Steel. The main difference between Stainless Steel and Duplex Steel is in composition i.e. they have a higher chromium content of 20–28% higher molybdenum, up to 5% lower nickel, up to 9% and 0.05–0.50% nitrogen content.

Duplex Steel are extremely corrosion resistant having high resistance to intergranular corrosion. Duplex Steel exhibits very high resistance to stress corrosion cracking even in chloride and sulphide environments. The high chromium content of Duplex Steel that protects against corrosion. At low temperatures Duplex Steels have superior ductility than the ferritic and martensitic grades and can readily be used down to at least -50 °C. Duplex Steel provides high mechanical strength and exceptional corrosion resistance properties.

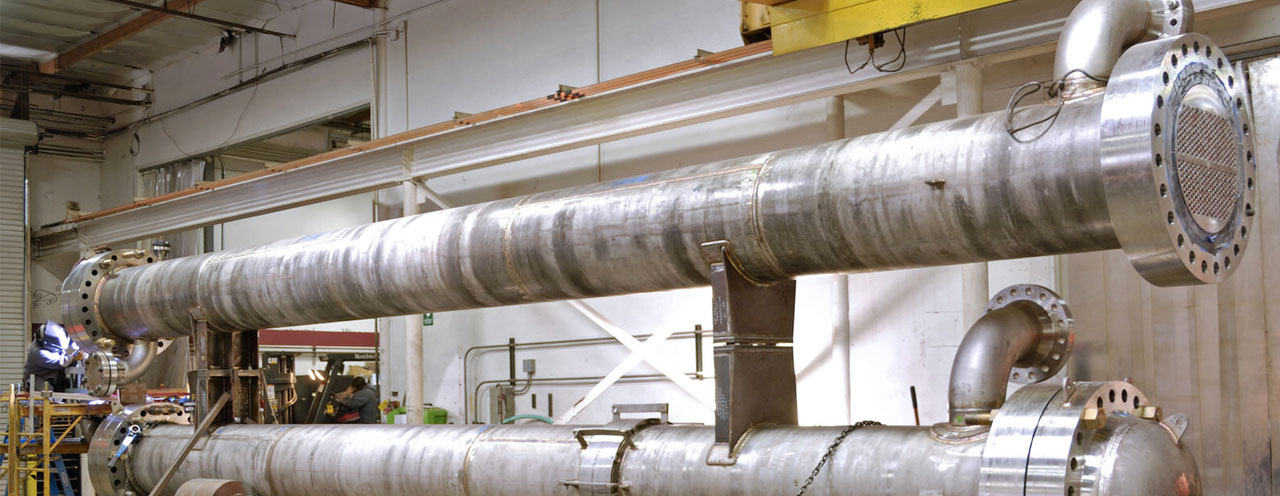

Duplex Steels are widely used for versatile applications in automotive, textile, fabrication, construction, ship building, paper and pulp, cement, aerospace defence, and heavy earth moving equipment. Duplex Steel is one of the primary constituents of any manufacturing industry or any industry that depends on machinery. They are widely used for versatile applications in automotive, textile, fabrication, construction, ship building, paper and pulp, cement, aerospace defence, and heavy earth moving equipment.